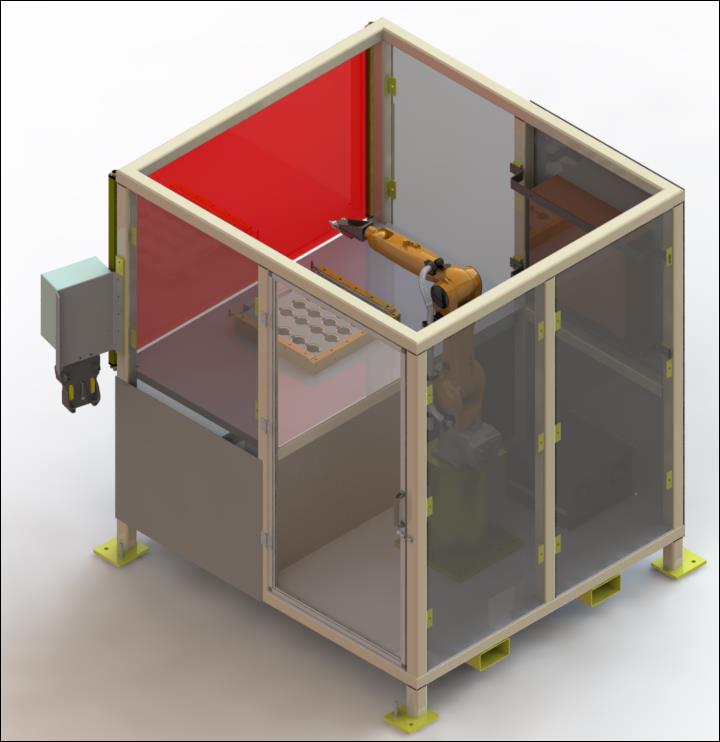

Robotic Adhesive Cell

| Robot Capacity | 10kg |

| Input Voltage | 460 VAC |

| Number of Phases | 3 |

| Robot Reach | 1101 mm |

Project Description

MJ Engineering Analyzed the Canopy Design of a new mine shuttle car, verifying that it conforms to mining standards.

Features/Benefits

Features

- Robot KUKA® KR 10R1100 sixx

- KR C4 Compact Controller

- KUKA smartPAD teach pendant

- Integrated Touch Screen operator panel

- Light curtain at operator access

- Portable Cell

- Short lead time

Benefits

Safety

- SICK Light curtains

- Door Interlocks

Reliability and Efficiency

- Allows speed and consistency that is not capable with manual procedures

- Increased production rates

- Eliminates setup time for operator

- Control System allows for storage and easy retrieval of multiple programs

- Easy access for maintenance

Portable

- Can be moved by forklift

- Store additional fixtures

Options

- Adhesive delivery system

- Temperature control system

- Size – the overall cell and fixture bed can be adjusted to meet specific needs

- Robot – the robot model and manufacture can be changed to fit specific requirements

- Turntable fixture mounting – allows simultaneous robotic application and operator load/un-load

- Integrated Vision Inspection/Guidance