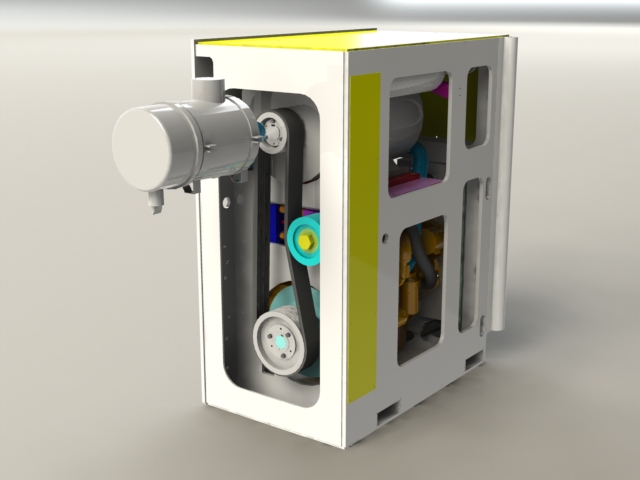

Integration of Diesel Motor within a Shuttle Car for the Mining Industry

To accomplish these tasks, MJ Engineering used a number of different design and engineering processes. We first designed a proper motor/generator mounting frame. Using the natural frequency of the motor/generator we were able to determine which frequencies to avoid so we could design the most stable mounting frame. Then we focused on designing a drive system linking the motor to the generator. Utilizing our outstanding design team we were able to eliminate the need for a battery pack or cable reel within the mining shuttle car. After all this work was completed, MJ Engineering was able to supply the client with 3D CAD models and CAD drawings of the final design.

To learn more about our outstanding design work on this project please contact MJ Engineering or see below for details.

Project Description

MJ Engineering was tasked with integrating a Diesel Motor and an Electric Generator in a mining Shuttle car.

Capabilities Applied/Processes

Design/Engineering

- Design Concept for Various Motor/Generator Mounting Frames

- Designed drive system linking Motor to Generator

- Used the Natural Frequency of Motor/Generator to Determine the Natural Frequency to Avoid When Designing Mounting Frame

- Created SolidWorks and Solid Edge 3D CAD Models & CAD Drawings of Final Design for Manufacturing

Features/Benefits

Process Requirements

- Package Motor/Generator within Existing Reel Compartment

- Ensure it is Easy to Maintain in a Mine environment.

- Use Motor/Generator System Provided by Client

Benefits

- Eliminates the need for a Cable

More Info

Overall Dimensions

Car: 352″long x 108″ wide x 93 ½” high Motor/Generator Compartment: 55 ¾ wide x 68 high x 32 ¾” deep

Material Used

Steel plate and tubing

Industry for Use

Mining

Mineral

Delivery Location

Canada

Standards Met

Customer supplied specifications

Product Name

Integration of Diesel Motor/Electric Generator into Mining Car