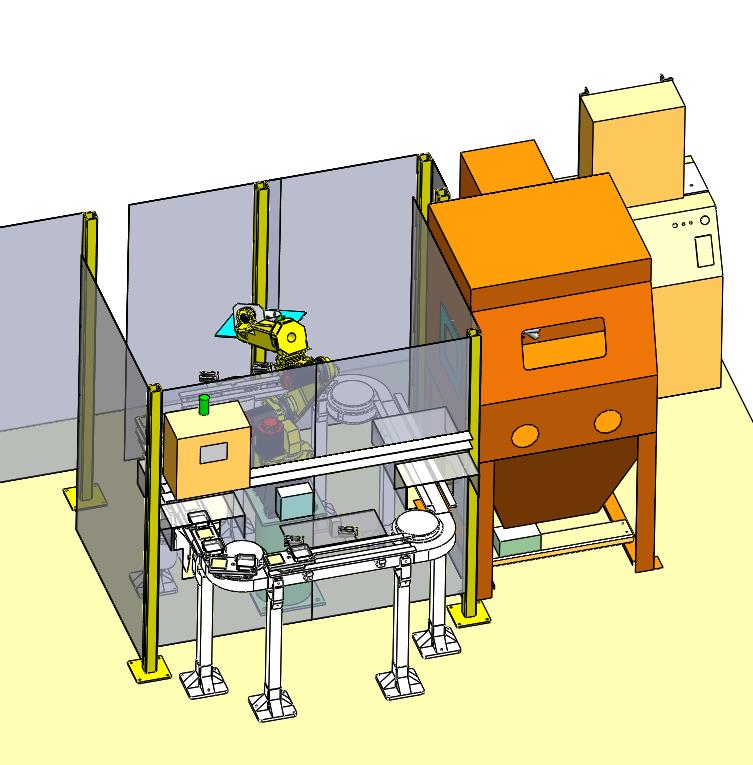

Custom Designed Robotic Cell for Shot Blasting

The robot uses a custom designed magnetic EOAT (End of Arm Tool) to pick multiple parts from a pallet and present them into a blast cabinet for finishing. The operator loads one of 12 pallets with a tray of unfinished parts then selects the specific processing program from the touch screen operator panel.

The pallets automatically index into and out of the cell as they are processed by the robot and the blast cabinets.

Project Description

This custom designed robotic cell is used for shot blasting a surface finish on very small parts.

Capabilities Applied/Processes

Cell Design

- Conception of cell that meets unique production requirements.

- Create SolidWorks© 3D models of cell concept

Tooling Design

- End Of Arm Tooling (EOAT) Design Integrated w/ a custom designed magnet lifting mechanism.

Installation

Start-Up

Operator and Maintenance Training

Features/Benefits

Features

Utilizes FANUC© M10iB robot with R30iA controller.

Parts are delivered into the cell via the circular pallet conveyor.

Ability to control all blast variables:

- Duration

- Presentation (angle and distance)

Benefits

Provides a fully automatic processing cell that requires minimal operator involvement.

Ability to pick variable part sizes for presentation to the blast.

The operator has easy access to the process control via the custom programmed touch screen operator interface panel.

More Info

Overall Cell Dimensions

10 ft. x 7 ft.

Size Capabilities

Part sizes up to 3 in. square

Tightest Tolerances

+/- 0.2mm

Material Used

Shot beads

In Process Testing Performed

Functional runoff (no blast materials) performed prior to delivery

Industry for Use

Specialty manufacturing

Delivery Location

Columbus, Ohio

Standards Met

Customer supplied print, 2D Auto CAD Drawing

Product Name

Custom Designed Robotic Cell for Shot Blasting