MJ Engineering used its expertise in robotic systems integration to help a client replace old, worn out capital equipment.

A company called on the experts at MJ Engineering to replace an old system that required constant maintenance and no longer met modern safety standards for mechanical equipment. The antiquated system used a fixed, mechanical assembly with cylinders and slides to put together components. MJ Engineering recognized right away that replacing the old mechanical system with a new robotic one would greatly increase its speed, capability, and reliability.

MJ Engineering and Robots to the Rescue

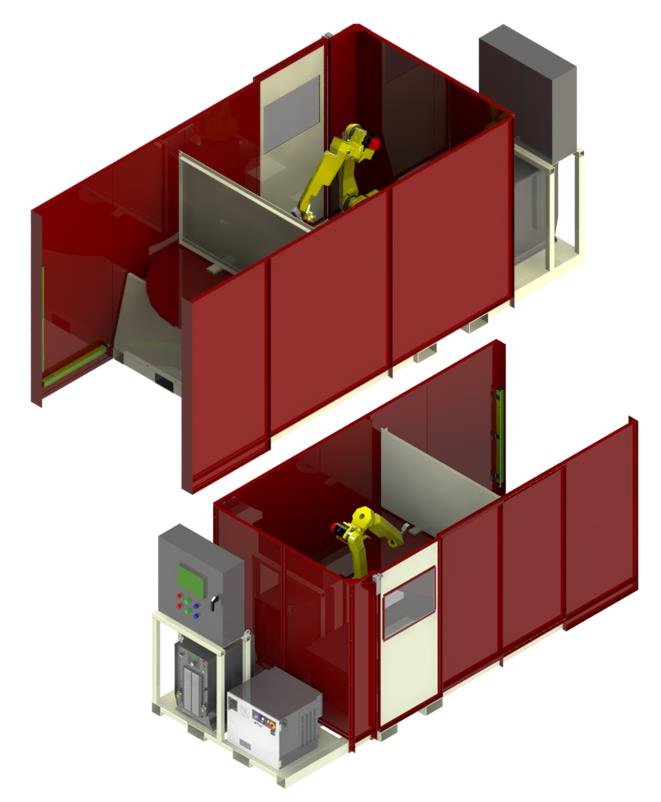

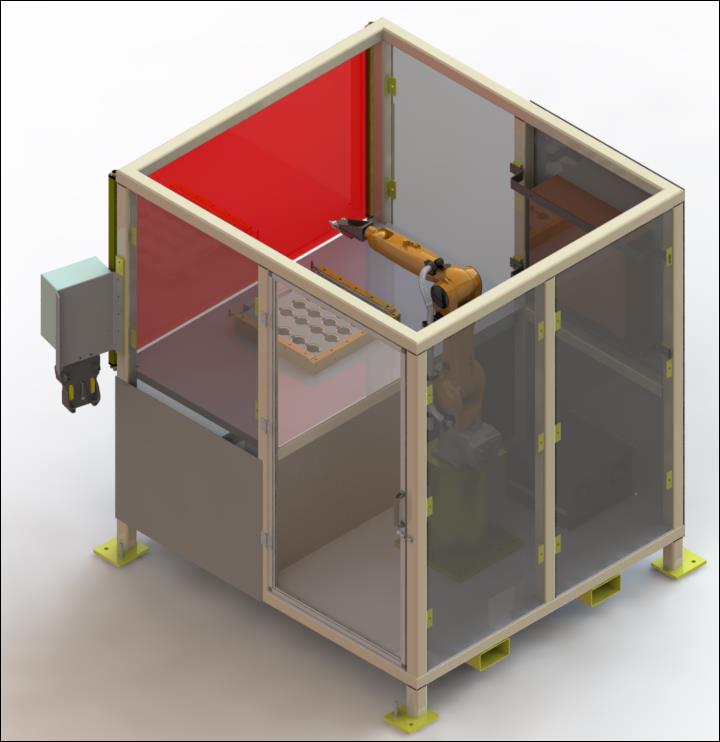

MJ Engineering created a new, safer, faster, and fully-automated system that includes three FANUC high-speed industrial robots. The robots use line tracking and vision guidance to accurately and quickly put together five–piece subassemblies.

Subassembly Components

Each subassembly consists of five reinforced plastic components:

- Base<

- Roller

- Divider

- Piston

- Top plate

>Robotic vision systems enable the robots to pick parts from the conveyors — in any orientation — place them precisely where they need to go.

Robots at Work

The system MJ Engineering created works like this:

- A human operator places a base on the conveyor.

- Robot 1 uses a robotic vision system to pick the base off the conveyor and place it into a nest on a turntable.

- Robot 1 then picks a roller from a bowl feeder escarpment and places it onto the base.

- Robot 2 places the divider (fed by bowl) and the piston (fed by conveyor) onto the base and roller.

- An alignment device orients the subassembly to put the piston in the proper position.

- Robot 3 takes the top plate from the conveyor (fed into the cell by a neighboring cell), aligns a plastic piece, and places the top plate onto the subassembly.

- A servo-driven actuator presses the subassembly shut and blows air into it to verify that the unit rotates, meaning the subassembly is a success.

The whole process takes approximately less than 10 seconds!

Human Machine Interface

While the robots are putting together the subassemblies, an operator can monitor the system using a human machine interface (HMI) mounted to the cell. The operator can use the HMI to correct faults or perform emergency stops and safety resets as needed. The main screen displays a picture of the dial table. Onscreen indicators provide the status of the machine as it operates. When a fault occurs, indicated by a flashing red light, the operator can access a more detailed screen that shows what is happening and where the fault is located. For maintenance and testing, the HMI also includes a password-protected screen with a button for every manual function of the machine. Supervisors can also use this screen to adjust speed, timing, and other settings.

Room to Grow

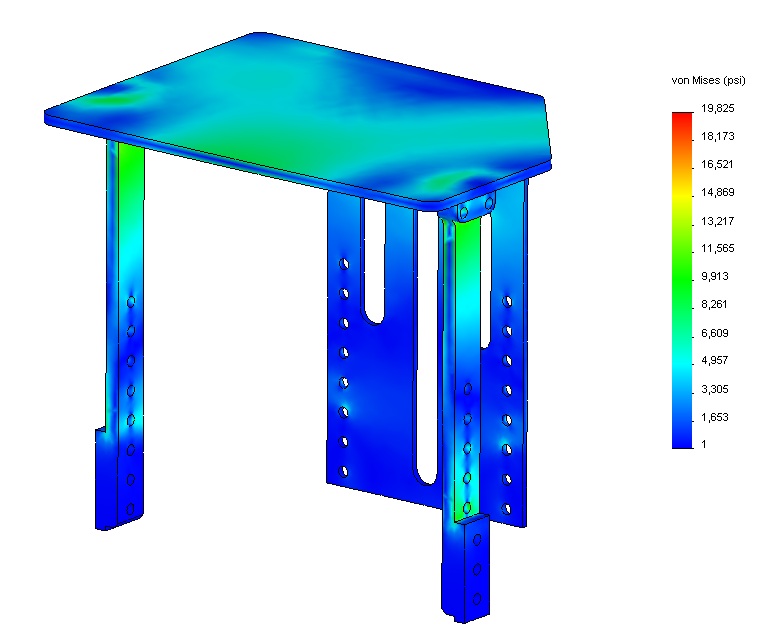

The cell can be physically adjusted to accommodate larger components.

MJ Engineering Is Your Resource for Robotic Systems

The subassembly cell is just one example of how incorporating robots can improve the safety and speed of an old manufacturing system—and how MJ Engineering can solve your needs with a customized solution. To learn more about our engineering and design services, please contact us at sales@mjengineering.com.

Subassembly Specs

For more details about this specific project, refer to the following table.

Capabilities Applied/Processes

- An electrical enclosure with an HMI to control the system

- Documentation provided in electronic and hard copy

- Training provided for operation and maintenance

Features/Benefits

- Makes one subassembly in ~9 seconds

- Conveyors are removable for easy belt replacement

More Info

Overall Dimensions

Width: 6 ft

Height: ~6 ft

Depth: 6 ft

Electrical Specifications

220/480 VAC, 3-Phase, 60 Hz

Material Used

Carbon steel, aluminum, and stainless steel