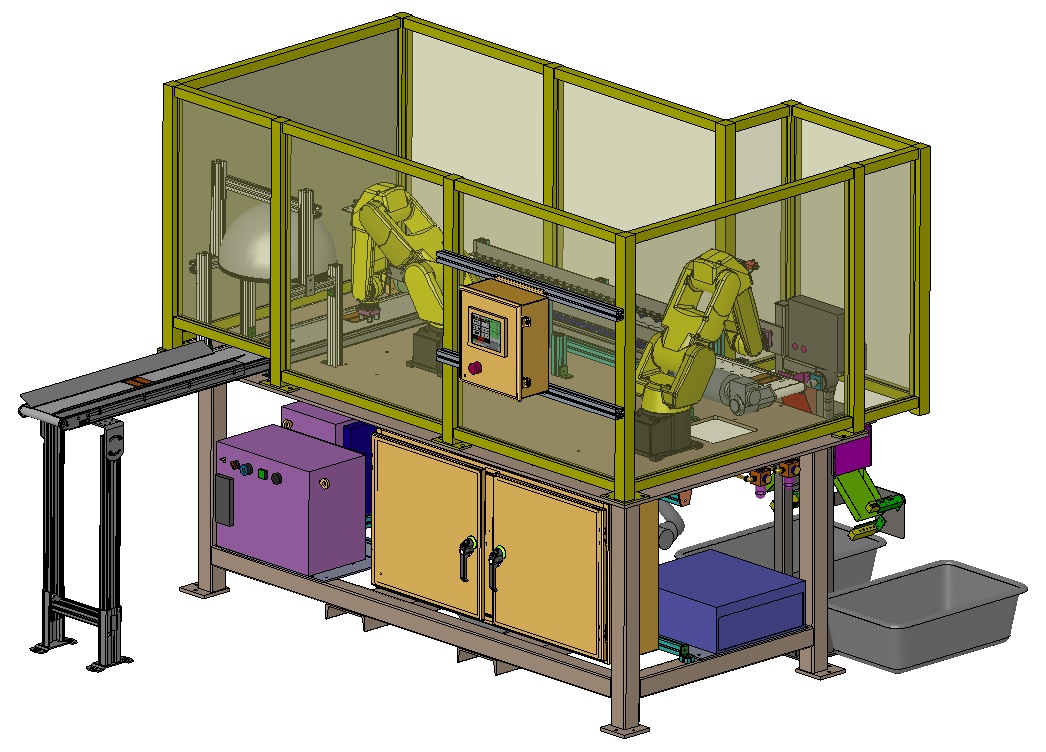

Custom Designed Inspection Robotic Cell for the Food Industry

A key feature of the inspection cell is the FANUC LR Mate 200iC 5H Series robot with integrated iRVision system, which provides highly repeatable and accurate placement of inspection items on the processing conveyor. MJ Engineering also provided electronic documentation, and operation training for equipment users, as well as ongoing long term product testing support.

Project Description

This Custom Designed Inspection Robotic Cell is used to inspect food products.

Capabilities Applied/Processes

Cell Design

- Conception of Cell that Meets a Variety of testing Protocols

- Create SolidWorks 3D Models of Cell Concept

Inspection System Design

- Must Interface with Custom Spec Inspection Devices

- Complete Detailed Cell Design

Installation

Start-Up

Documentation

- Provided ElectronicallyTraining

- Operation Training Provided

Long Term Product Testing Support

Features/Benefits

Features

- Utilizes FANUC LR Mate 200iC 5H Series Integrated iRVision System

- Automated Product Tracking

- Orients Packages on Incoming Conveyor Line

- Up to 60 Individual Units Per Minute

- Positive Rejection of Identified Defect Packages

Benefits

- Vision System Provides Accurate & Repeatable Placement on the Processing Conveyor

- Greatly Reduces need for Destructive Testing

More Info

Overall Cell Dimensions

Length: 96″

Width: 48″

Height: 72″

Tightest Tolerances

Pick and Place within 1mm

Material Inspected

Nutritional Supplements

Industry for Use

Food

Delivery Location

Ohio

Standards Met

Customer supplied specifications

Product Name

Custom Designed Robotic Cell for Food Inspection